Introduction

In this guide we’ll show you how to properly install the ReadyAIR Primary Air Suspension for the 2014+ RAM 2500.

READ INSTRUCTIONS THOROUGHLY AND COMPLETELY BEFORE INSTALLATION.

INSTALLATION BY A CERTIFIED PROFESSIONAL MECHANIC IS HIGHLY RECOMMENDED.

LOGIQTM IS NOT RESPONSIBLE FOR ANY DAMAGE OR FAILURE RESULTING FROM IMPROPER INSTALLATION.

Note: If your ReadyAIR product has a damaged or missing part, please contact customer service directly at 800-549-4620 and a new replacement part will be sent to you immediately. For warranty issues, please return to the place of installation and contact LOGIQ via email at tech@LOGIQair.com.

WARRANTY

LOGIQTM provides a limited lifetime warranty to the original purchaser of products, that the product be free from defects in workmanship and materials when used on cars and trucks as specified by LOGIQTM and under normal operating conditions. This warranty is subject to the requirements and exclusions set forth in the full Limited Warranty and Return Policy that is available at logiqair.com/warranty. Air compressors are a wearing component and are covered by a 2-year warranty from the date of purchase. The warranty does not provide coverage for abuse, operation in a manner not consistent with the product’s design, or damage resulting from exposure to the elements.

WARNINGS & DISCLAIMERS

By installing this product you acknowledge that the suspension of this vehicle has been modified. As a result, this vehicle may handle differently than that of factory-equipped vehicles. As with any vehicle, extreme care must be used to prevent loss of control or roll-over during sharp turns or abrupt maneuvers. Always wear seat belts, and drive safely, recognizing that reduced speeds and specialized driving techniques may be required. Failure to drive this vehicle safely may result in serious injury or death. Do not drive this vehicle unless you are familiar with its unique handling characteristics and are confident of your ability to maintain control under all driving conditions. Some modifications (and combinations of modifications) are not recommended and may not be permitted in your state. Consult your owner’s manual, the instructions accompanying this product, and state laws before undertaking these modifications. You are responsible for the legality and safety of the vehicle you modify using these components.

| APPLICATION NOTES |

| TRUCK COMPATIBLITIY |

| ALL TRUCK VARIATIONS COMPATIBLE |

| 5TH WHEEL COMPATIBILITY |

| ALL HITCHES ARE COMPATIBLE |

Tools

Parts

- Driver Side Air Spring Assembly

- Passenger Side Air Spring Assembly

- 1/2"-13 Weld Nut Bracket × 2

- 1/2"-13 x 1.25" Hex Head Bolt × 4

- 1/2" Flat Washer × 4

- 3/8"-16 x 0.75" Hex Head Bolt w/ Threadlocker × 4

- 3/8" Flat Washer × 4

- 2mL Red Threadlocker Packet

- Heat Wrap

- Hose Clamp × 2

- 8" Zip Tie × 16

- Inflation Valve to 1/4" PTC Fitting × 2

- 16' Roll of 1/4" Air Line

-

-

Note original ride height measurement from center of rear fender arch to ground.

-

Safely lift truck and support with jack stands under the frame.

-

-

-

With the suspension drooped:

-

Un-bolt the upper sway bar end-link bolt on each side.

-

Un-bolt one side of the pan-hard bar.

-

Un-bolt the lower shock bolt on each side.

-

Now there should be enough room to remove the factory coil springs and isolators.

-

Check the spring perches to ensure all pieces have been removed and there is no debris in the mounting areas.

-

-

-

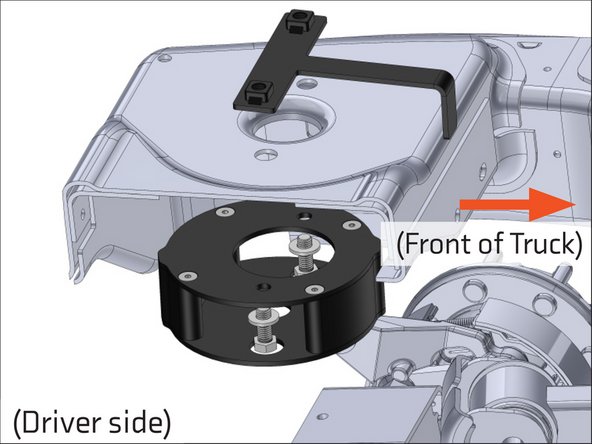

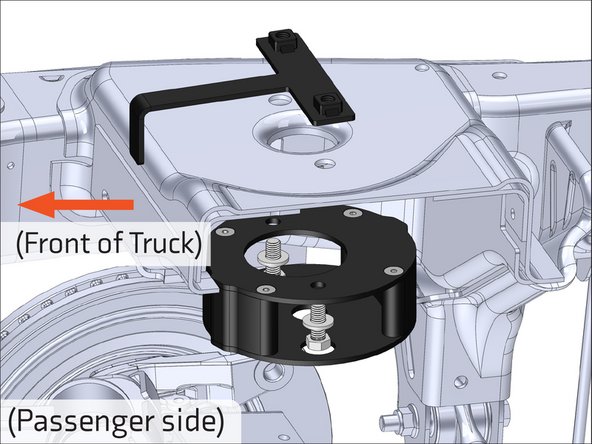

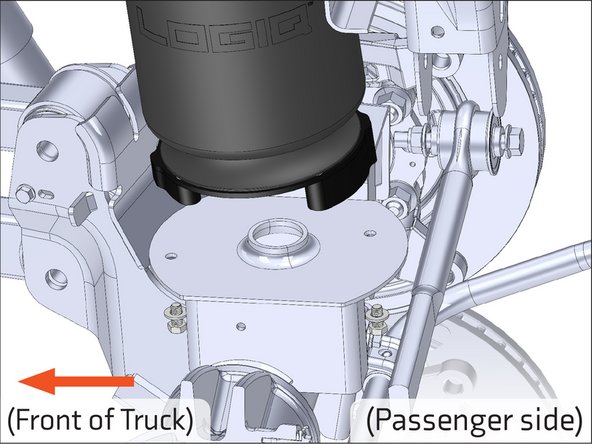

Place the weld nut bracket on top of the crossmember, with the bent tab facing the front of the truck, and line it up with the two holes shown.

-

Apply some threadlocker to two of the provided 1/2" bolts.

-

Using a 3/4" socket with an extension, thread the 1/2" bolts, with washers, into the weld nuts.

-

The weld nut bracket will likely move around so you will need to hold it in place to line up the bolts with the weld nuts.

-

Torque the bolts to 75 FT. LB.

-

Repeat process for passenger side.

-

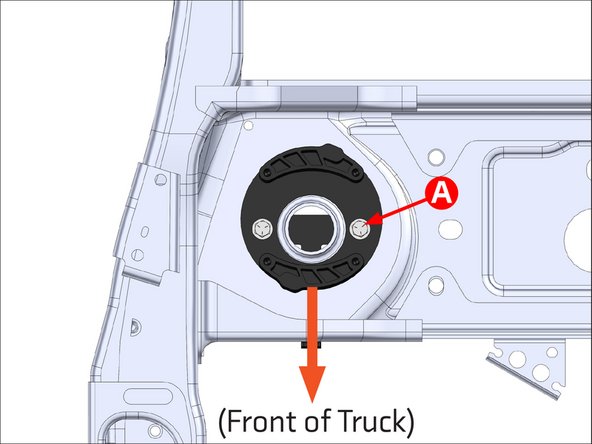

MAKE SURE THE UPPER BRACKET HOLE IS ORIENTED TOWARDS THE FRONT OF THE TRUCK.

-

-

-

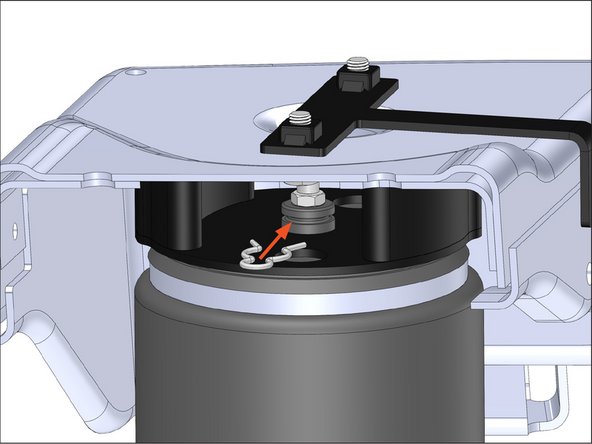

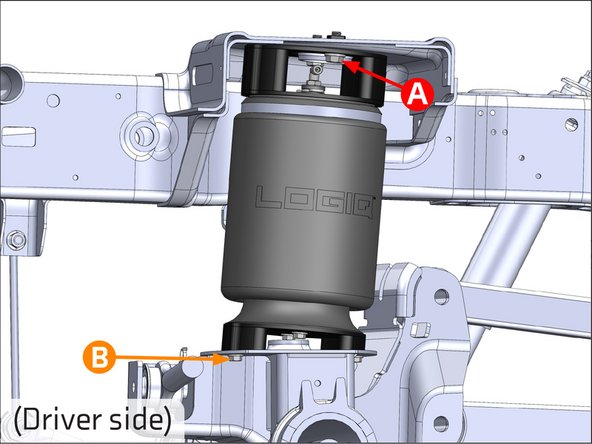

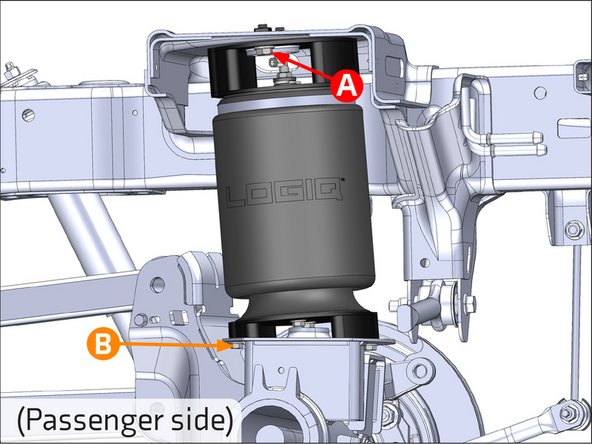

Grab the lower part of the air spring assembly and insert the elbow fitting through the center hole on the upper bracket, making sure to not damage the fitting.

-

Press on one of the provided hairpin clips in the groove shown on the air spring.

-

Repeat for the passenger side.

-

-

-

Press down on the lower bracket to bring it in contact with the axle perch.

-

Install the provided 3/8" bolts and washers into the bracket through the two perch holes shown.

-

Repeat for the passenger side.

-

On the driver side, using a stubby 9/16" wrench to start the highlighted 3/8" bolt will be helpful due to the limited space.

-

-

-

75 FT. LB.

-

Torque the lower bracket hardware to 20 FT. LB.

-

-

-

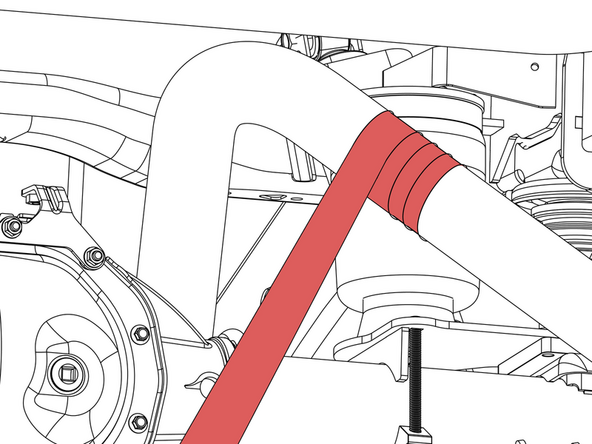

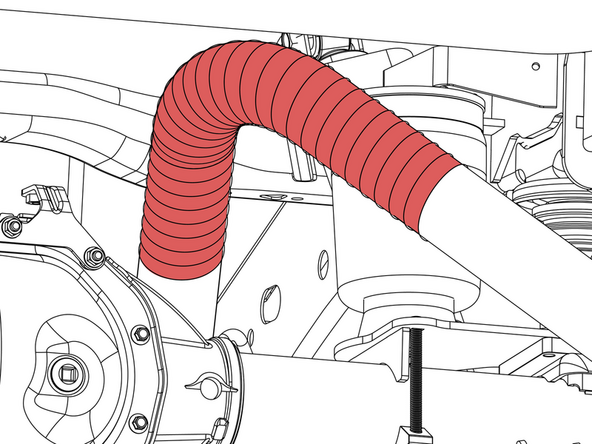

Begin 12 inches behind the air spring and wrap toward the front of the vehicle.

-

Ensure you have overlap that is about half the thickness of the heat wrap like shown.

-

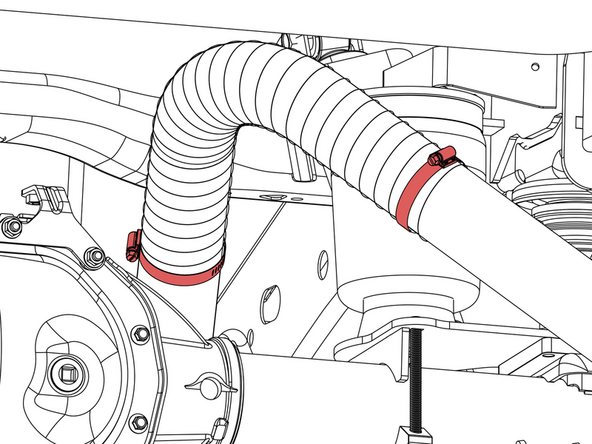

Once the whole roll has been wrapped onto the exhaust, attach the provided hose clamps to each end of the wrap as shown.

-

Ensure the wrap extends at-least 12 inches in front and behind the air spring (more is better if there is enough wrap).

-

Trim any excess clamp stick-out with a pair of metal snips.

-

-

-

When used with an on-board air management system, refer to the on-board air management system installation instructions before routing the air lines.

-

When not using an on-board air management system, mount inflation valves at desired location using 5/16" drill bit

-

Route air line from each inflation valve to each air fitting on both of the air spring assemblies. Avoid hot exhaust and sharp edges. Cut air line square and free from burrs with air line cutter or razor blade!

-

-

-

Check for leaks at fittings with soapy water.

-

Verify all fasteners are torqued properly.

-

Use a tape measure and inflate the air springs until the ride height matches the original ride height measurement from center of rear fender arch to ground. Note – This will be your unloaded air spring pressure setting and can be varied from 0” to +3” based on user preference.

-

Congratulations! You have successfully installed your new ReadyAIR kit!

If you have any questions or concerns, please contact LOGIQ at 800-549-4620.

Congratulations! You have successfully installed your new ReadyAIR kit!

If you have any questions or concerns, please contact LOGIQ at 800-549-4620.